Why the carrier tape and cover easily crack

Not only in food and drug industry, peeling force tester also could be used for carrier tape test.

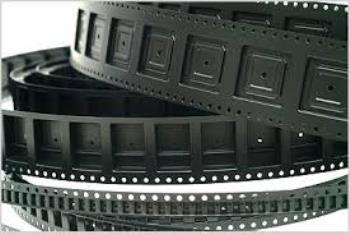

The carrier tape is mainly used in the electronic component mounting industry. Carrier tape sealed with cover (cover tape), take resistors, capacitors, transistors, diodes and other electronic components in the carrier with pockets. It sealed by cover tape with the formation of closed packaging for protection electronic components from affected by pollution and damage in transit.

In fact carrier tape and cover tapes easily crack is caused by the mismatch of the carrier tape and the upper cover band. First we have to analysis the two products basic materials. The original material is PC, PS, ABS etc.. The upper cover is generally based on the material PET. The two materials are not compatible with the different chemical composition, or the melting point is different will lead to adhesion too tight or loose. . Second we could test the peeling force by carrier tape peeling tester.

To meet the needs of the cover with the carrier compatible with, we should add chemical additives in the process of manufacturing, or combine with some chemical materials.

Carrier tape peeling force tester

Therefore, to solve the problem of carrier tape sealing cracks, we have to test peeling test of carrier tape and cover by SMD carrier tape peeling force tester; Second we have to do aging test ensure that the two products are tested at different times by simulating different external environment and conditions. And to ensure that the compatibility of the upper cover belt and download belt after the test is a single and sealing conditions of the fixed.

- 2020-11-13

- 2020-11-06

- 2019-01-19

- 2018-12-15